Screw-driven home lifts

The origin of the screw use for passenger elevators

An elevator (or lift) facilitates the action of traveling up and down vertically. Originally, elevators were invented to relieve the efforts required to move objects to different levels, even before being developed to be suitable & safe for passengers use.

In Europe, the first elevator invented for passenger use was screw-driven, using the working principle of the screw and nut movement, which is a simple and safe. Removing the risk of the elevator “falling” out of the equation.

Screw-driven home lifts have been very popular in Europe for many decades before spreading the trend to other continents, like the Middle East and Asia.

With land prices constantly increasing, the residential market needed to adapt, building taller structures on smaller plots. With a growing number of homes reaching up to 6 floors, the need for home lifts to access to a more comfortable daily life started to play an important role.

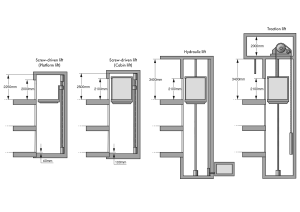

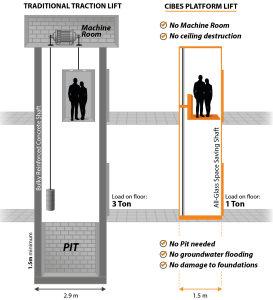

Home lifts come in a variety of technologies including traction, hydraulic, screw and vacuum. While traction is the most used technology, it is often preferred for tall building with a need of high speed, but requiring a large footprint and infrastructures not required for other technologies like screw-driven home lifts.

We, at Cibes lift, emphasize on this technology as it has the best compromise in terms of high safety, minimal civil work and design for use in a home.

Screw-drive technology, in addition to being extra safe to use, is packed with features providing assistance in case of emergencies.

The technical aspect of a screw-drive is extremely simple. It eliminates heavy structural work that is unneeded for a home lift. It takes up much less space to set it up, leaving more usable space in the house.

Because screw home lifts can come with a structure called a built-in shaft, it is self contained and extremely fast to assemble as it has been custom made in the factory according to the exact dimensions requested and agreed on. Its materials can be selected depending on the needs/design (steel or glass) without the need to build a concrete shaft.

In addition, the fact that Cibes home lift shafts are made of aluminum, it makes a huge difference in its total weight. Thus, having a positive effect on reducing the load on the floor structure.

Whenever the need to build a concrete shaft is not necessary to support the home lift, a question comes to your mind:

How to prepare the desired location to install the home lift?

When the elevator comes with a built-in shaft, the homeowner is not required to dig a pit at the first floor. Nor does he need to build a machine room on the top floor thanks to the self contained motors integrated in the platform or cabin where the nut is connected to the screw.

When choosing to install a screw-driven home lift, the homeowner always win by saving himself from the hassle of having to find multiple contractors / technicians to prepare the job site. It reduces the problem of untidy & lengthy site preparation such as scattered cement dust, problems with mortar, cleanliness, problems with workers leaving jobs done halfway. Plus, the the engineering behind building a proper elevator shaft, pit and machine room require specialized knowledge.

All those factors can be very disturbing for an existing home with a whole family living in it.

So when you can avoid having to hire builders to prepare the job site for the home lift, why wouldn’t you? Homeowners can also keep costs under control for site preparation and elevators (with shafts).

To summarize, choosing a screw home lift with a built-in shaft that can be installed in as little as 4 days, in a quiet and clean way, it could be the best math you could do for yourself.

With an equal standing space (left and right), note the space required for the traditional lift on the left compared to the space saving Cibes lift on the right.

FAQ:

Q: How does the cost of installing a screw-driven home lift with a built-in shaft compare to other types of home lift installations, particularly in terms of initial investment and long-term maintenance?

A: The cost of installing a screw-driven home lift with a built-in shaft may vary depending on factors such as the size of the lift, customization options, and installation requirements. While initial investment costs might be comparable to other types of home lifts, the long-term maintenance costs of screw-driven lifts could potentially be lower due to their simpler mechanical design and reduced need for infrastructure like machine rooms or extensive pit construction. However, specific cost comparisons would depend on individual project specifications and should be discussed with Cibes Lift.

Q: What are the limitations or potential drawbacks of screw-driven home lifts compared to other technologies, such as traction or hydraulic lifts, especially in terms of weight capacity, speed, or adaptability to specific architectural designs?

A: Screw-driven home lifts offer numerous advantages, including safety, simplicity of design, and space-saving features. However, they may have limitations compared to other lift technologies. For instance, screw-driven lifts might have lower weight capacities or slower speeds compared to traction lifts, making them less suitable for certain applications such as high-rise buildings or installations with heavy traffic demands.

Q: Are there any regulatory or safety considerations unique to screw-driven home lifts, particularly regarding compliance with building codes, inspection requirements, or emergency protocols, and how does Cibes Lift address these concerns in their installations?

A: Regulatory and safety considerations for screw-driven home lifts are crucial aspects addressed by Cibes Lift. Compliance with building codes, safety European standards, and inspection requirements is paramount to ensure the safety and reliability of home lift installations. Cibes Lift adheres to relevant regulations and standards in the design, manufacturing, and installation of screw-driven lifts, ensuring that installations meet or exceed safety requirements. Additionally, Cibes Lift provides comprehensive training and support to homeowners on emergency protocols, maintenance procedures, and regulatory compliance to ensure safe and compliant operation of their home lifts.